Retrofit

In the wheel and tire industry potential vibrations are monitored by measuring the harmonics of a wheel. As is the case with a lot of equipment taking an old machine which is mechanically sound and updating the controls is a extremely cost effective, when compared to buying a new machine..

Why : In the wheel and tire industry potential vibrations are monitored by measuring the harmonics of a wheel. As is the case with a lot of equipment taking an old machine which is mechanically sound and updating the controls is a extremely cost effective, when compared to buying a new machine..

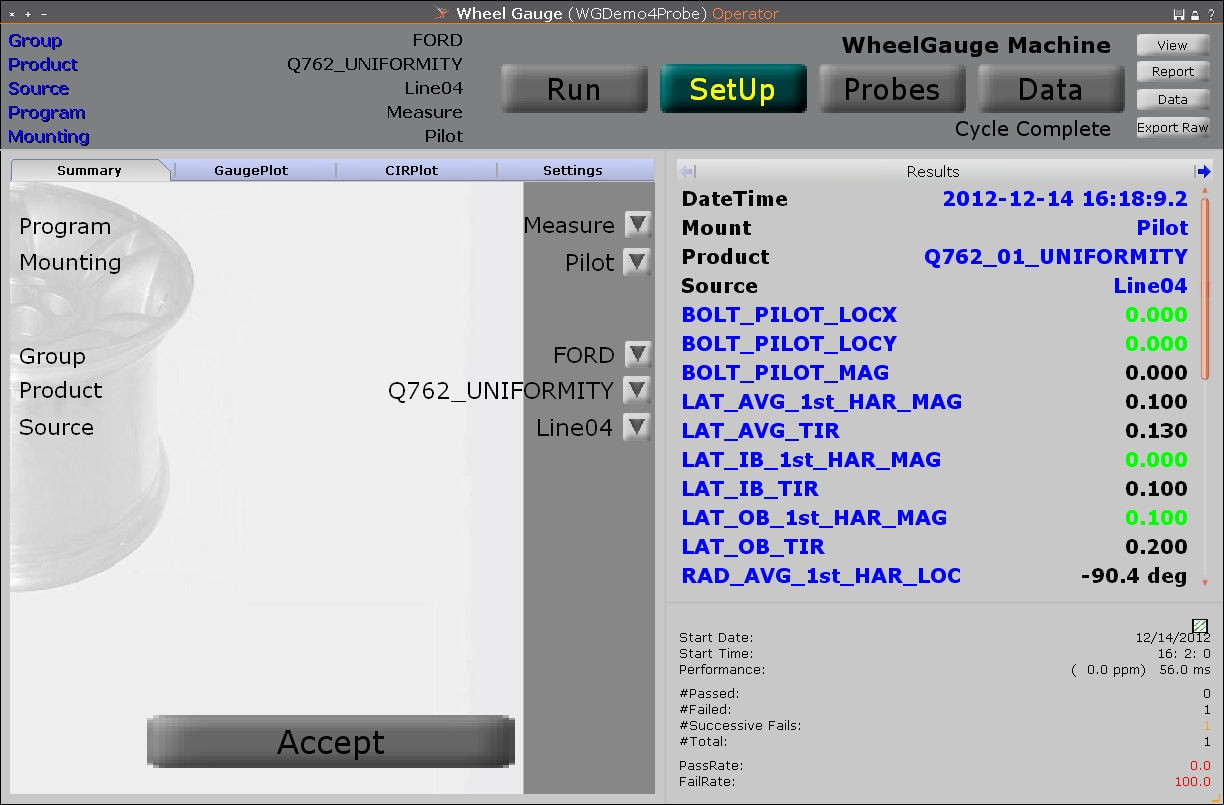

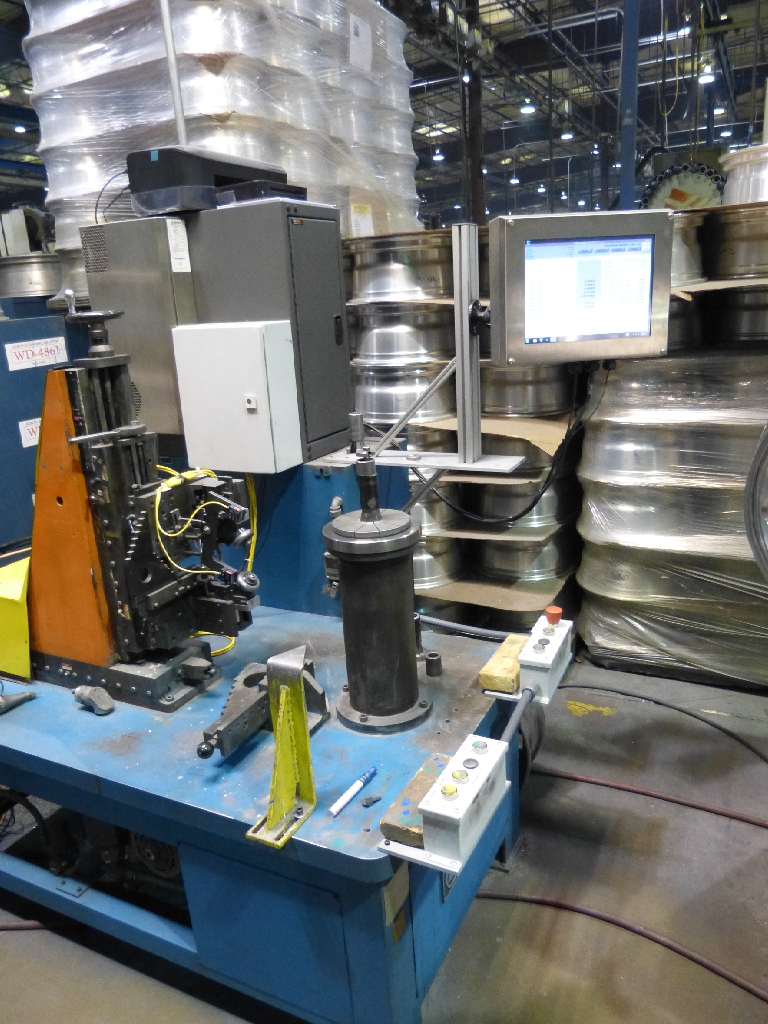

What : Here an old Akron standard gauging machine is updated. The goal is to measure the run outs, harmonics and harmonic locations of a wheel. These need to be within customer specification. The goal is to stop the wheel at the low or high point. Being a industrial environment the operator interacts with a touch screen or buttons on the machine. The operator can select the wheel type, run the program, and print the results as necessary. The system logs all results.

Advantages/Benefits. :

- Automation Manger is very flexible and can integrate diverse hardware very quickly

- Retrofitting an old machine improves its accuracy, speed, and makes for a reliable machine

- Huge cost saving

- Rejects wheels that will exhibit out-of -spec. vibrations

- Tailored user interface to customer needs

- Ability to run the machine with different tolerance configuration

- Reduced setup time. Typical setup for a new wheel type is less than 5 minutes for data entry of tolerance settings. This can be done remotely and the setup file is transferable between machines

Automation Manager Features Used :

- SPC analysis

- XML product wheel description files (configured by the end user)

- Calibration of stop distance

- Calibration of gauges

- Print reporting

- SPC Reporting

- Data Export to a csv file for excel import

Hardware :

- Solartron digital probes 32bit (Orbit series)

- IO card for machine control ie advance retract head . (Adlink PCIe 7250)

- Encoder card for measuring encoder position(Measurementcomputing Quad 4)

- Computer (Lenovo 32bit Win 7)

- Touch Screen

Operation :A Wheel rim is placed on the machine. The operator has set the machine for the selected wheel size and selected the tolerance specification file. He presses the two measurement buttons. The software advances the head, rotates the wheel and while reading the encoder monitors the probes positions. Additionally an input tells the software the location of the valve hole. The harmonics are calculated and the wheel stopped and retracted. Screens are available to show the measurements done, the probe vs encoder plots or an exaggerated wheel low point drawing. This is all configured inside Automation Manager software

Safety :

- System monitors for over travel and retracts head if operator sets machine wrongly

- Dual hand operation required to run machine

- if the valve hole input is not found the system operates as normal, stopping the wheel as required. The angle measurement is no longer zeroed to the valve hole. A warning is given to the operator.

Typical System Performance :

- Measures up to 1024 reading per revolution

- Wheel speed approx 40 rpm

- System accuracy typically 15-20 microns

- Measurement time 3-5 revolutions:

- 2 revolutions for measurement

- 1 for stop

- 1 for start up/valve hole location