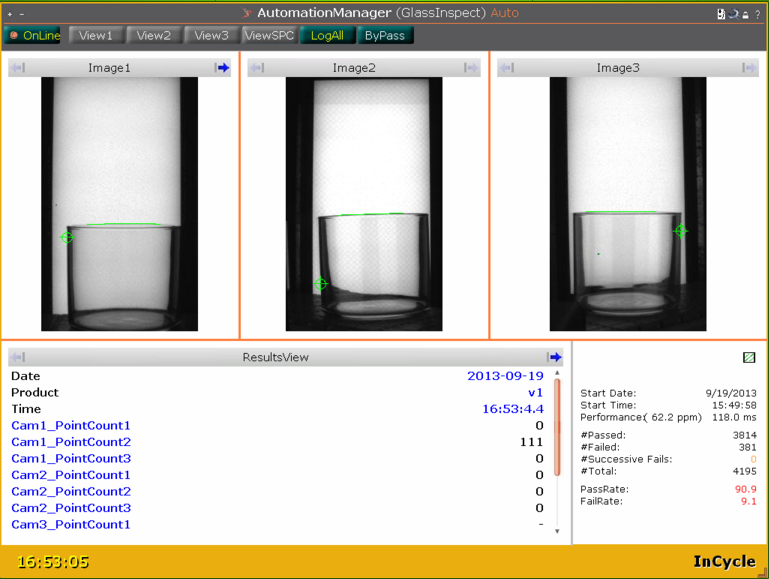

Inspection of Glass Faces and Glass Rims

Why :

Glass manufacturing requires inspection of product for defects in the glass like bubbles or edge defects etc. Product rates are typically 120 - 180 parts per minute

Advantages/Benefits. :

- Automation Manger is very flexible and can integrate diverse hardware very quickly

- The cost saving of Automations Manager with off-the-shelf cameras compared to the industry standard machines is huge. Factor of 10:1

- Logging reject images for post analysis

Automation Manager Features Used :

- Fault logging, with defect images viewable while running

- Setting tolerances can be adjusted while the product is running

- Automation Manager manages the io and delays to the reject blow offs using internal shift registers

NOTE no PLC required

Hardware :

- PCI advantech IO card

- Epix cameras

- I7 PC

Operation :

A Wheel rim is placed on the machine. The operator has set the machine for the selected wheel size and selected the tolerance specification file. He presses the two measure buttons. The software advances the head, rotates the wheel and while reading the encoder monitors the probes positions. Additionally an input tell the software the location of the valve hole. The harmonic are calculated and wheel stopped and retracted. Screens are available to show the measurements done, the probe vs encoder plots or an exaggerated wheel low point drawing. This is all configured inside Automation Manager software

Typical System Performance :

- Typical product rate are 120-180 part per minute